Piano Maker’s Corner: Rising From the Ashes: The Origins of Phoenix

Meet Doug Chapman, Head Piano Technician for Phoenix Pianos, a British piano company located on the picturesque Hurstwood Farm, near Sevenoaks in Kent, England! He and Richard Dain, founder of Hurstwood Farm Piano Studios and engineer/designer of the Phoenix Carbon Fiber Piano. I’m very excited that they will be regular contributors to the Piano Maker’s Corner column. In today’s column Doug tells the tale of a totally new piano risen from the ashes of total disaster.

One wouldn’t think that dropping a grand piano down a flight of stairs could ever end well. Indeed, nor did I.

Mercifully no one was seriously injured or killed, but the noise of its death was said to be horrific.

However, opportunity came from the jaws of disaster when piano removers rolled our treasured Bosendorfer Imperial Grand piano down eight stone steps of a church where it had been used for recording. Examination showed the frame was intact, but the soundboard had come away in one piece from its seat and the action frame was seriously bent. All the keys had fallen out and the bat pins, which position the keys, were seriously bent and displaced. The case was crushed scratched and damaged.

One can repair almost any piano but after an event of this magnitude one never knows what hidden damage may be lurking to strike at a critical moment with buzzes rattles and creaks. Effectively we could not sell the piano were it repaired nor ever use it for recording or performance again for many years. Insurers, as they almost always do, told us the piano was never of any value anyway, although we had been paying a premium based on many tens of thousands of pounds based on our purchase price from Bosendorfer.

Months later we suddenly got a cheque for more than we had claimed for our losses. No one ever explained why but our solicitors told us to return the excess. We were then asked if we would like to buy the wreck for £4000. We had been looking for a piano to use for research of ideas we had, and leapt at the opportunity of rebuilding this previously superb unique instrument to incorporate some of these.

Our Imperial thus rose like a Phoenix from the ashes of its catastrophic demise. The name stuck with new developments done on it.

Bridge Agraffes: Improving on Traditional Design

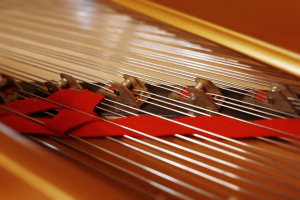

By then we had encountered Stuart’s innovative pianos from Australia and wanted to assess the merits of his bridge agraffes; these are clips that hold the string against the bridge of the piano. Traditionally inclined pins are used in what is called a pin bridge. We had been allowed to see Stuart’s pianos at a distance but knew nothing of the detail of his agraffes.

By then we had encountered Stuart’s innovative pianos from Australia and wanted to assess the merits of his bridge agraffes; these are clips that hold the string against the bridge of the piano. Traditionally inclined pins are used in what is called a pin bridge. We had been allowed to see Stuart’s pianos at a distance but knew nothing of the detail of his agraffes.

We therefore designed a bridge agraffe of our own, starting with a blank sheet of paper. As an engineer in diesel engines I knew something of bolting attachments and saw the opportunity to increase the contact forces between the strings and the bridge cap while eliminating the downwards loading on the soundboard (called down-bearing) that is a consequence of traditional scaling design. That downwards force, typically over half a ton, has two disadvantages:-

1) The load causes progressive collapse of the soundboard and consequential loss of contact between the strings and the bridge via which energy reaches the sound board.

2) The load also clamps the soundboard inhibiting its response to the input of vibration energy.

Our first attempts produced shrill but powerful sound, but our computer analysis showed the efficiency of transmission of energy from the string to the soundboard was almost doubled. We experimented with selective sound energy filtering with important success in controlling sideways vibration, but the filtration acted inefficiently on the longwise vibrations in the strings. It was clear that where the strings lie against the surface of the bridge in a conventional pin bridge, the friction is beneficial in damping these unwanted and clashing lengthwise vibrations.

Further work showed that the main benefit from our new agraffes came from unloading only the bass notes. We began to make pianos with hybrid bridges; that is with our bridge agraffes on the bass notes and conventional pin bridges on the higher notes. Everybody liked the sound quality but we were sacrificing power by still applying a down bearing load on the soundboard in the top notes.

Our latest step is to design a pin bridge that develops a high contact force between the string and the bridge but applies little or no down bearing (clamping) load to the soundboard. This became possible by applying our then expanding knowledge of carbon fibre design to produce a carbon fibre bridge able to tolerate the higher stresses that this new design caused in the bridge wood material. Stresses under which a wooden bridge would be operating are uncomfortably near the limits of tolerable stress in the wood material.

A carbon fibre bridge has other merits. It can –indeed must- be shaped by machining rather than hand carving. This is far more accurate and improves sound uniformity in the piano. This bridge was first applied on our carbon fibre piano. Anyone interested can see and play it at the forthcoming Frankfurt Music Fare. The power and sustain of this piano in these upper registers is really exciting.

Carbon Fibre Soundboards: Taking Pianos into the 21st Century

Since mid-2007 we have been experimenting with and building carbon fibre sound boards for pianos. The reason we started this is that the industry wisdom states that the best soundboard is made of material that has high elastic properties (known as Young’s Modulus) and low density. All engineers know that carbon fibre offers these properties to a higher extent than any other readily available material including metal alloys. That is why warplanes and racing cars are now being made of carbon fibre.

Since mid-2007 we have been experimenting with and building carbon fibre sound boards for pianos. The reason we started this is that the industry wisdom states that the best soundboard is made of material that has high elastic properties (known as Young’s Modulus) and low density. All engineers know that carbon fibre offers these properties to a higher extent than any other readily available material including metal alloys. That is why warplanes and racing cars are now being made of carbon fibre.

A newly discovered form of carbon called “Fullerine” is even better but is not yet available for general engineering. Fullerine is a mouth-watering opportunity for the ultimate piano soundboard but on balance of probability it will not be possible to try it in practice for a couple of decades.

Our work has been in researching the effect of board thickness, fibre type and orientation, bridge stiffness and ribs on the performance of pianos. Some of these things have huge influence and others quite small influence. With designs where there are many choices, engineers need to follow a practice called “hill climbing” in which the best way to choose what to do with each is selected. Traditionally piano performance has been improved by technician designers with “golden ears”, but since hearing response is conditioned by health, tiredness, ambient conditions and many other factors we had to establish a more scientific means of assessment.

With help from professional computer programme writers we developed a programme that enabled us to determine the natural vibration frequencies of a complete piano/soundboard system and could so thus design these to correspond with the notes of the piano in the range of all the notes. We quickly showed that the upper notes of most pianos have ample matching natural frequencies but there can be too few of these around the bass notes, especially with small pianos. However with the massive power of this innovative computer programme we can now design soundboard/ bridge/ case systems for pianos in which the whole piano sound is much improved.

This technology is now used in our range of Phoenix pianos with carbon fibre soundboards. In our Carbiano (wholly carbon fibre) piano we have taken this to the ultimate peak of “hill climbing”. People visiting the Frankfurt Music Fare can play this 170cm baby grand piano and make their own judgement whether it challenges the performance of a typical 9 foot concert grand.

Next Month: We’ll be explaining why we decided to use carbon fibre actions in our pianos and how the exceptional keyboard feedback allows the average pianist the ability to play to an undreamt of standard.

Thanks for the comment Raymundo. So pleased you enjoyed the article. More to come soon. It’s true, you never stop learning! You’re very welcome to visit our showroom/workshop anytime! Doug.

Learning never stops does it? Thanks so much for reading Piano Addict!

Wow! As a 59 year old Klavierbauer trained in the “old school”, it means I better learn some more (which I’m more than willing, given a chance of course!

Only dead people stops learning, and I’m alive & kicking, so I better learn from you guys out there in UK, kindly keep me posted !

Cheers!