Piano Maker’s Corner: Jigs & Seasoned Wood

Many of you have asked for more on the process of designing and manufacturing a new brand of American pianos. Today Daniel talks about some of the everyday things and the setbacks that have occurred during the last few years.

Many of you have asked for more on the process of designing and manufacturing a new brand of American pianos. Today Daniel talks about some of the everyday things and the setbacks that have occurred during the last few years.

Since we started our business endeavor more than seven years ago, it has been a pleasure and an incredible amount of hard work. Working in the piano shop causes one to appreciate the machinery that we stumble upon in everyday life. We have become so accustomed to the machines surrounding us, that we no longer notice them. It is simple to identify the problem when creating something, but in the end that part may or may not work.

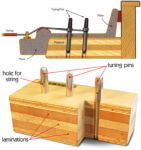

It is incredible to think of how much effort went into custom making one special shop machine, a jig, in order for that jig to create an item for everyday use. Now, jigs are not easy to make and they do not always work as planned for many reasons. Jack, an independent contractor and a wonderful friend, attempted to create a jig in order to help restrain a piano during a build. Unfortunately, in the end, the jig did not do the job and we had to find another solution. Also, every time it broke, it took a copious amount of time to be fixed since a new part then had to be created to fix each problem.

At the shop, it takes about six to seven months to build a new piano. Various piano parts must first be acclimatized before we can work with them. For instance, the wood for soundboard and the bridges must be acclimatized for over a year in order for us to be able to work with them without any difficulties. If they are not, they are prone to breaking or cracking when used with various jigs. A successful completion of a piano involves a generous amount of time and patience; special attention to detail is very important, especially when working on dampers.

There are hundreds of parts in a piano, and every single one of them has their own difficulties. Of course, diligence and the long hours pay off afterward when a beautiful piano is completely finished. So the next time you play the piano, think of the time and effort that has gone into making the parts in order to create the incredible instrument, as well as the machinery that helps built the piano itself.

Daniel Ley is the owner of Ley Piano Company in Tucson Arizona, where he carries on a tradition of quality piano care, service, and restoration. In addition to full service piano care, he and his craftsmen build their own modern American grand piano, Monserrat.

Wow, I do some woodworking but can’t even imagine the craftsmanship that goes into building a piano from scratch. Amazing.